Innovative Solutions in Industrial Machinery

Aktitanyum Endüstriyel Makina San.

Modernise your industrial production processes and enhance efficiency with Aktitanyum Industrial Machinery.

About Macline

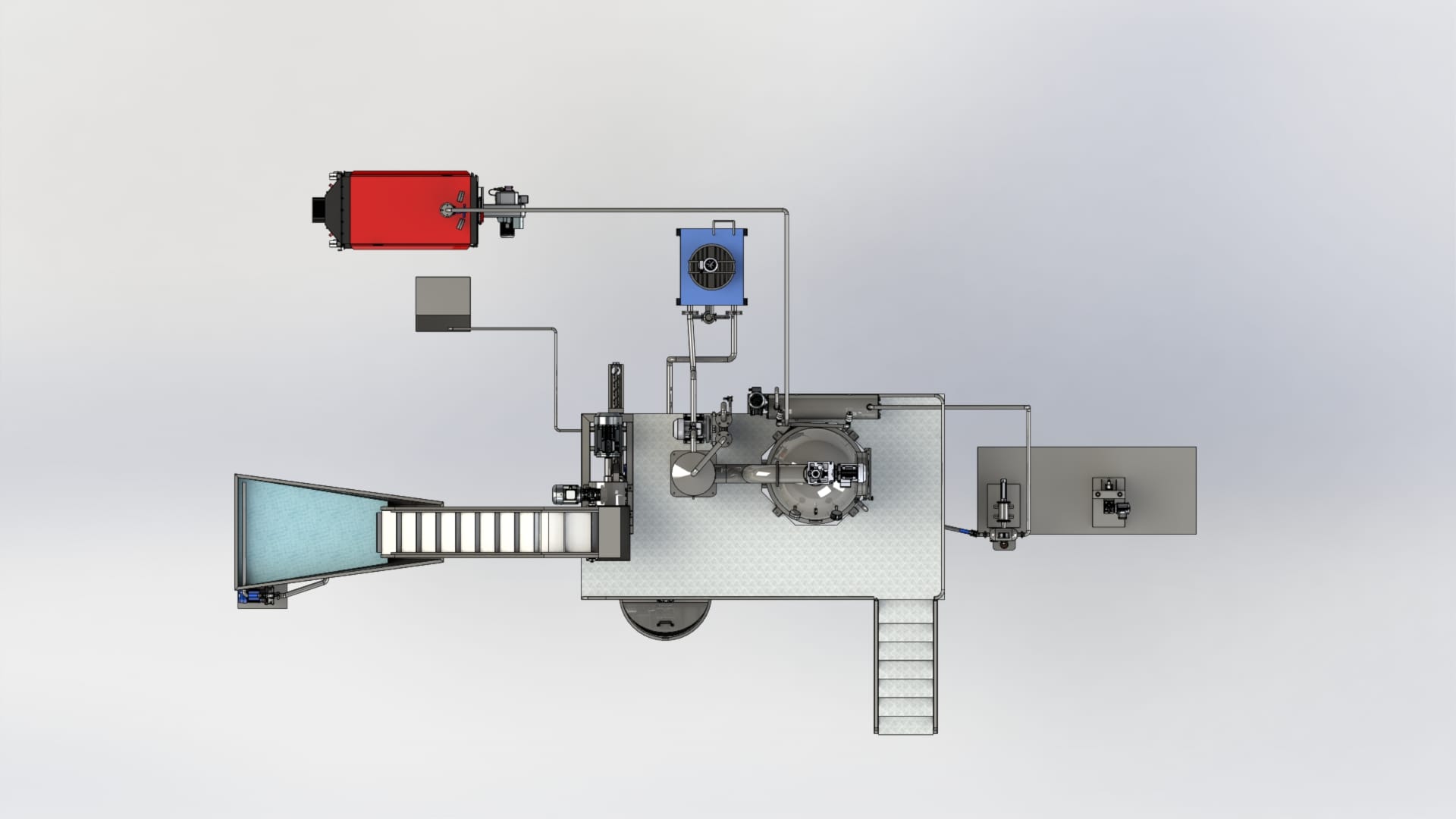

MACLINE is a leading brand offering innovative solutions in industrial machinery production. By combining a modern design approach with technical expertise, we are committed to providing our customers with high-quality food processing equipment at the lowest possible costs. With years of experience in the industry, we aim to enhance the efficiency and effectiveness of your production processes. Our mission is to develop sustainable and technological solutions in industrial production, thereby boosting our clients' competitive edge. You can watch the animated video of our small-scale tomato paste facility next to this text.

Watch The Facility Operation Video

Key Features

Advantages Of MACLINE Products

High Efficiency

Our products are designed to ensure maximum efficiency in your production processes.

Contemporary Design

Our elegant and functional designs cater to both the aesthetic and technical needs of your business.

Energy Savings Solutions

Reduce your costs with innovative technologies that minimise energy consumption.

User Friendly Interface

Minimise operator training duration with our intuitive interfaces at Aktitanyum Endustriyel Makina San.

Durability

Our machines, renowned for their durability and robust build, represent a wise long-term investment for your business.

Flexibility

We offer modular structures tailored to meet your diverse manufacturing needs.

İşlenebilir Ürünler

TOMATO PASTE

PEPPER PASTE

PIZZA SAUCE

MAYONNAISE

KETCHUP

MUSTARD SAUCE

POMEGRANATE SAUCE

LEMON SAUCE

Macline Model Table

The standard production line is designed for the efficient processing of tomato paste and sauces.

Elektrik: 17 kW/h

Steam: 150 kg/h

Kapasite: 250 kg/h

Basic Model

The homogenizer production line is ideal for ketchup and mayonnaise.

Elektrik: 21 kW/h

Steam: 150 kg/h

Capacity: 250 kg/h tomatoes, 200 kg/h ketchup

Additional Feature: Homogenizer

Double concentrate unit, high-capacity tomato processing.

Elektrik: 28 kW/h

Steam: 300 kg/h

Kapasite: 500 kg/h

Ek Özellik:

Çift Konsantre Ünitesi

Homojenizatör

Dual-line and pepper processing, large production capacity.

Elektrik: 40 kW/h

Steam: 350 kg/h

Kapasite: 500 kg/h

Additional Feature:

Pepper Processing

Double Concentrate

Sauce Processing

The fruit processing line is suitable for fruit juice production.

Elektrik: 25 kW/h

Buhar 200 kg/h

Capacity: 250 kg/h tomatoes, 150 kg/h fruit juice

Additional Feature:

Crushing Mill

Filtering Equipment

washing pool

Washing basin with continuous circulation provided by a conveyor system

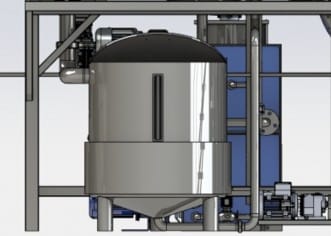

product tank

Preheating capable mixer-equipped stock mash tank

evaporator

Thanks to its special design, it cooks the product to the highest quality and in the shortest time possible while preserving its color and flavor.

pasteurization

The product is sterilised by heating it up to 92 degrees, and its unique design helps maintain the integrity of its colour.

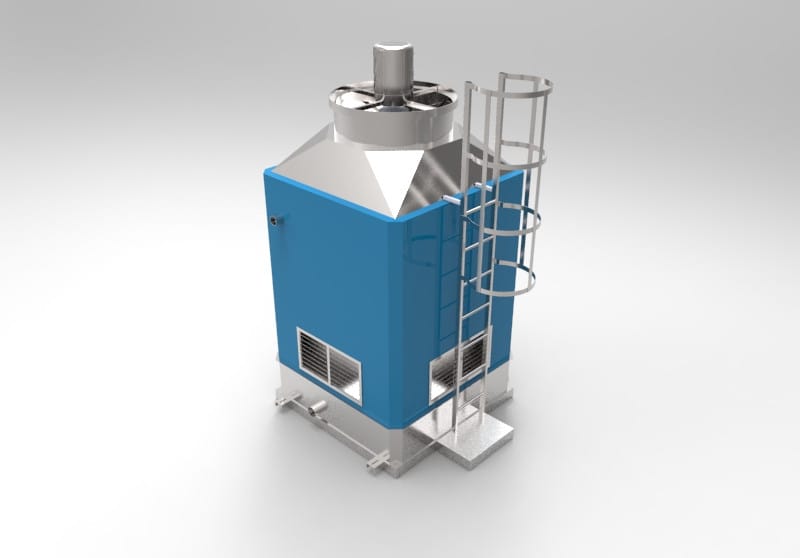

cooling tower

In businesses where cooling water is insufficient, it is utilized to effectively cool the water.

steam boiler

The steam energy required for cooking tomato paste is generated by a steam boiler equipped with comprehensive safety features.

Turbo extractor

The machine effectively separates the seeds, skins, and juice of the tomatoes, featuring a waste conveyor specifically designed for the skins and seeds.

fillling head

900 g filling head and jar sealing unit suitable for hot filling technology

MACLINE Industrial Tomato Paste Production Lines: High Efficiency, Low Energy Consumption, and Modern Technology

In today’s highly competitive food production industry, manufacturers need production lines that deliver high capacity, low operating costs, and consistent product quality. MACLINE industrial processing systems provide exceptional advantages, especially for the production of tomato paste, pepper paste, pizza sauce, pomegranate molasses, lemon sauce, and various homogenized products.

Engineered with modern industrial principles, MACLINE equipment stands out with its energy efficiency, modular design, high hygiene standards, and user‑friendly operation. This makes MACLINE an ideal solution for both small businesses and large‑scale producers.

Key Advantages of MACLINE Production Lines

1. Energy Efficiency and Low Operating Costs

All motors used in MACLINE production lines are classified as IE2 or IE3 energy‑efficient motors, providing up to 20% energy savings compared to conventional motors. For example, the MACLINE ECO model consumes only 17 kW/h, making it one of the most economical production lines in its class.

This advantage significantly reduces operating costs, especially during long production cycles in tomato paste processing.

2. High Capacity with Minimal Labor Requirement

MACLINE systems are designed to operate at high capacity with minimal labor. The ECO model can run at full performance with only 4 unskilled workers + 1 technician.

This feature greatly reduces labor costs, particularly during peak tomato processing seasons.

3. Modern Design That Maximizes Product Quality

Thanks to MACLINE’s vacuum cooking technology, products maintain:

- Their natural color

- Fresh taste and aroma

- Minimal risk of burning or caramelization

As a result, tomato paste, pepper paste, and sauce varieties are produced with premium quality, smooth texture, and consistent homogeneity.

4. Modular Structure for Multi‑Product Production

MACLINE production lines are fully modular. On a single line, manufacturers can produce:

- Tomato paste

- Pepper paste

- Ketchup

- Mayonnaise

- Mustard

- Barbecue sauce

- Fruit juice

- Marmalade varieties

This flexibility allows investors to operate year‑round production with a single system.

How the MACLINE Tomato Paste Production Process Works

MACLINE’s modern process flow ensures fast, hygienic, and efficient production:

- Washing Tank – Raw materials are thoroughly cleaned.

- Crushing & Peeling (Pulper) – Seeds and skins are separated.

- Pre‑Heating Tank – Product is heated and prepared for concentration.

- Vacuum Cooking Unit – Product is concentrated at low temperatures.

- Pasteurizer – Shelf life is extended.

- Filling Unit – Hot or cold filling options are available.

This workflow ensures high efficiency and continuous production, especially in tomato paste processing.

MACLINE Models: Tailored Solutions for Every Production Need

MACLINE’s product family is optimized for different capacities and production requirements:

- MACLINE ECO – Standard production line

- MACLINE Plus – Equipped with a homogenizer for sauce production

- MACLINE PRO – Dual concentration units for uninterrupted production

- MACLINE PREMIUM – Includes pepper processing line + high capacity

- MACLINE JUICE – Designed for fruit juice and fruit processing

Each model can be customized according to the production goals of the facility.

SEO‑Optimized Keywords

This article naturally includes the following SEO‑friendly keywords:

- tomato paste production line

- industrial tomato paste machine

- pepper paste processing line

- industrial sauce production

- vacuum cooking system

- food processing machinery

- MACLINE production line

- energy‑efficient processing equipment

- homogenizer sauce machine

Conclusion: More Efficient, More Profitable, and Higher‑Quality Production with MACLINE

MACLINE industrial production lines offer manufacturers high capacity, low energy consumption, superior product quality, and modular production flexibility in tomato paste and sauce processing. With its modern design, durable stainless‑steel construction, and user‑friendly interface, MACLINE is a trusted partner in the food processing industry.

Whether you operate a small facility or a large‑scale production plant, MACLINE helps you achieve more efficient, more economical, and more professional production results.