Revolution In Ketchup And Mayonnaise Production

Innovative Technology for Exceptional Efficiency

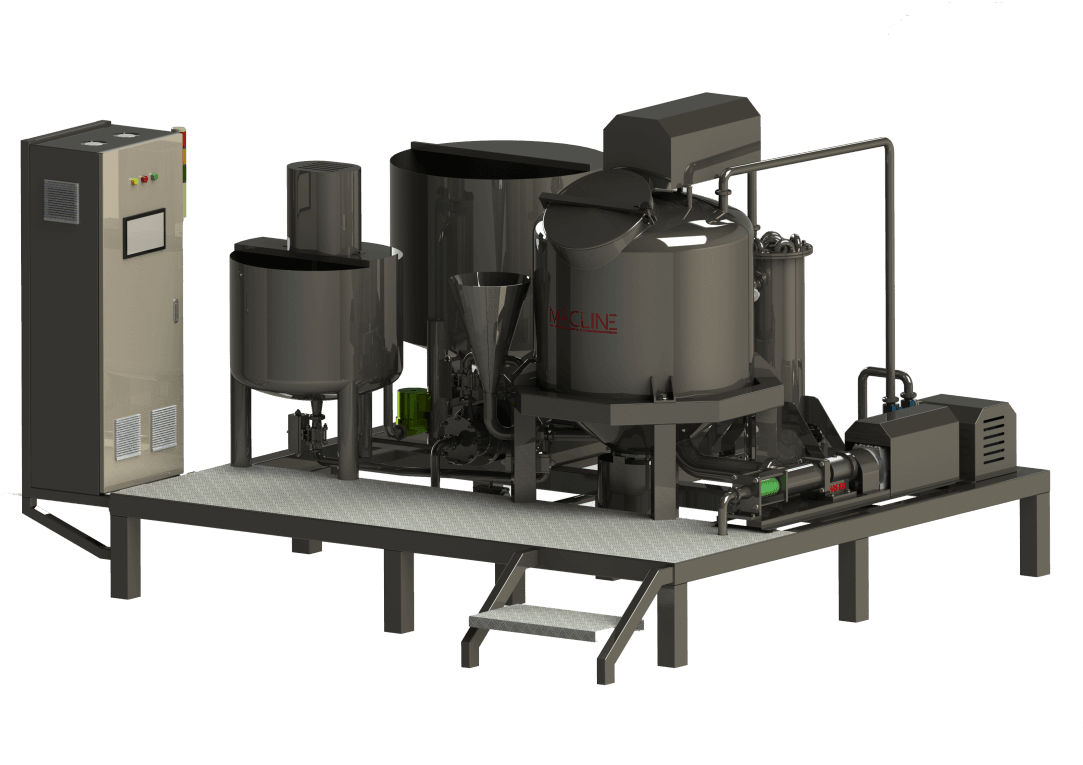

At Aktitanyum Endustriyel Makina San, we are revolutionising the production of tomato paste and sauces with our state-of-the-art machinery, optimising your production processes. Discover our patented homogeniser and advanced sauce processing technology.

Ketchup And Mayonnaise Machine Features

High Capacity

Aktitanyum Endustriyel Makina San provides robust models that can achieve production rates of up to 2 tonnes per hour, effectively catering to the needs of large-scale manufacturing with its impressive production capabilities.

Specialised Processing Technology

Aktitanyum Endustriyel Makina San offers specially developed processing technology that enhances product quality, providing a single solution for challenging formulations.

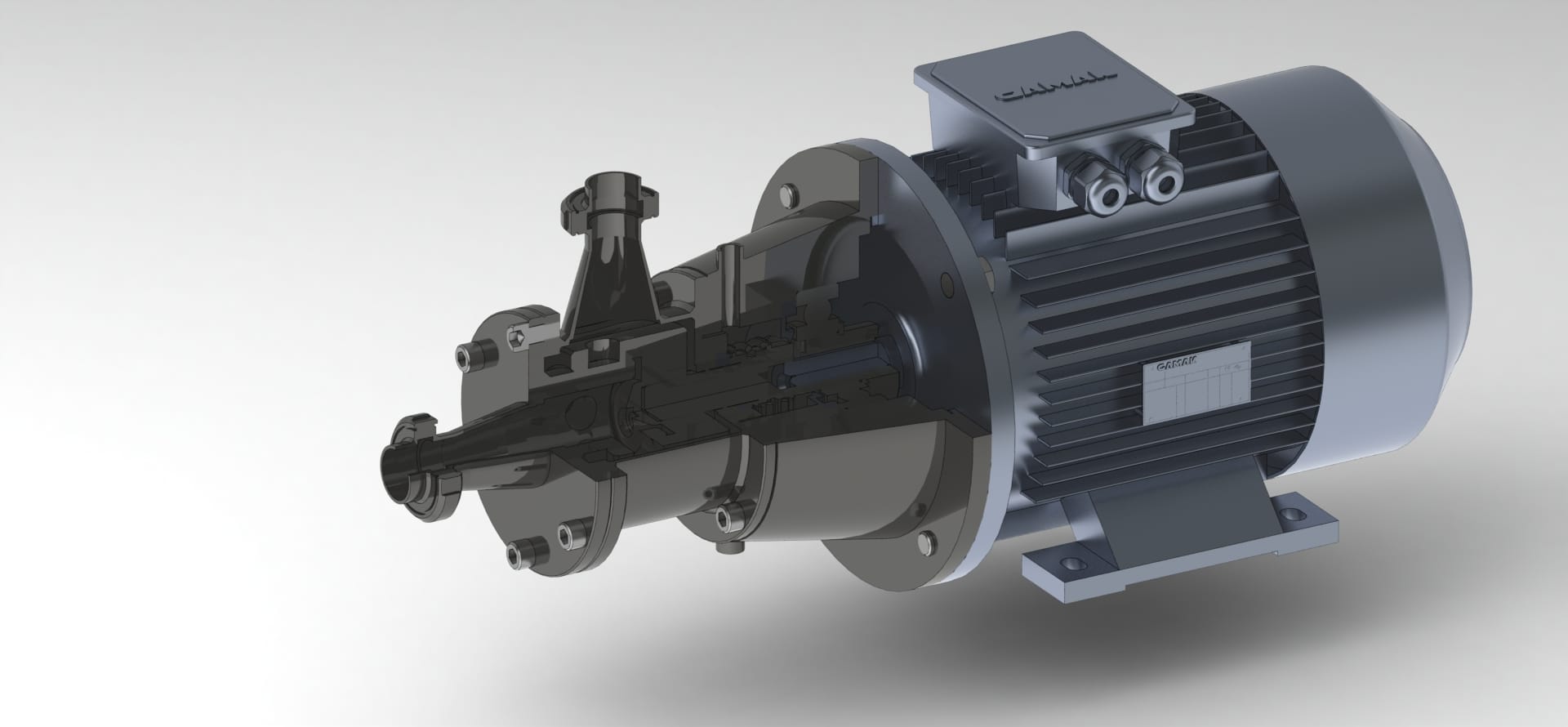

Patented Homogeniser

The patented homogeniser system ensures exceptional uniformity and consistency in your products.

Product Comparison

MAC-SC-300

Ideal for medium-scale production, offering exceptional capacity and efficiency.

Capacity: 300L

Reliability : %85

Energy: Low

MAC-SC-600

This model is engineered for exceptional performance in large-scale production environments.

Capacity: 600L

Reliability : %90

Energy: High

Efficiency Statistics

Our patented homogeniser reduces energy consumption by 30% while shortening processing time by 25%

Energy Efficiency

Reduced Processing Time

Capacity Increase

Special Processing Technology

Aktitanyum's patented homogenizer enables you to produce more homogeneous and consistent products while consuming less energy compared to other homogenization systems in the industry. Thanks to its advanced technology, it not only improves energy efficiency but also enhances product quality, thereby accelerating your processing operations. This not only reduces your production costs but also allows you to adopt an environmentally friendly approach, achieving a sustainable production process. With 30% less energy consumption compared to traditional methods, it combines taste and quality while maximizing efficiency in your production. Discover Actitanium and experience this revolutionary technology for yourself.

As Aktitanyum Industrial Machinery Manufacturing, we take pride in our special processing technology that revolutionizes ketchup and sauce production. This technology ensures materials are mixed homogeneously while maximizing flavor and quality. Our machine optimizes your production processes with its user-friendly interface and high efficiency.

Machine Photo Gallery

Machine Images

Cost-Effective High-Quality Filling Head

🧴 Why This Head for Ketchup and Mayonnaise Filling?

1. Flow Control in Viscous Products

Products such as ketchup and mayonnaise can cause problems during filling, such as air bubbles, splashing, or insufficient weight.

The MACLINE filling nozzle minimizes these problems thanks to its special flow channels and suction system.

2. Hygienic Filling – Food Safety

All product contact surfaces are made of stainless steel.

Thanks to its leak-proof seal structure and easy-to-clean modular design, it is fully compliant with food safety standards.

3. Adjustable Weight – Flexible Production

With an adjustable filling capacity ranging from 100 grams to 900 grams, it can be used for both small packages and large jars.

4. Low Investment Cost – Fast Return

It is much less expensive than high-capacity automatic systems.

The investment cost is recouped in a short time, making it ideal for businesses engaged in seasonal production.

Cost-Effective Filling Nozzle for Efficient Ketchup and Mayonnaise Production

In industrial food production, the filling stage plays a crucial role in maintaining product quality and ensuring high production efficiency. Especially for high-viscosity products such as ketchup, mayonnaise, and mustard, standard filling machines often fail to deliver the required precision. The cost-effective filling nozzle developed by MACLINE offers an economical, hygienic, and flexible solution for this need.

This article provides a detailed overview of the technical features, advantages, and production benefits of this industrial filling nozzle designed specifically for ketchup and mayonnaise applications.

Technical Features: Optimized Filling Nozzle for Ketchup and Mayonnaise

The MACLINE filling nozzle operates with a semi-automatic system and is suitable for both hot and cold filling. Its flow channels and precision control mechanisms are engineered specifically for viscous sauces, ensuring accurate and consistent filling.

- Filling Range: Adjustable from 100 to 900 grams

- Material: 304-grade stainless steel for all product-contact surfaces

- Filling Type: Compatible with piston or pump-assisted systems

- Viscosity Compatibility: Ideal for high-viscosity ketchup and mayonnaise

- Cleaning: Easy-to-remove parts, fully CIP compatible

- Energy Consumption: Low power requirement (approx. 0.55–1.1 kW)

- Operation: Single-operator use with button or foot-pedal control

These features make the nozzle an excellent choice for enhancing existing ketchup filling machines or mayonnaise filling equipment, as well as for new production lines.

Why Choose This Filling Nozzle for Ketchup and Mayonnaise?

1. Superior Flow Control for Viscous Products

Products like ketchup and mayonnaise can cause issues such as air bubbles, splashing, or inaccurate filling. The MACLINE filling nozzle minimizes these problems with specially designed flow channels and an optional anti-drip suction system, ensuring clean and precise filling.

2. Hygienic Design and Food Safety

All product-contact surfaces are made of stainless steel, ensuring full compliance with food safety standards. The leak-proof sealing structure and dead-zone-free internal design make cleaning fast and effective.

3. Flexible Filling Range for Different Packaging Sizes

With an adjustable filling capacity from 100 to 900 grams, the system is suitable for both small ketchup sachets and large mayonnaise jars. This flexibility is ideal for manufacturers serving multiple product segments.

4. Low Investment Cost and Fast ROI

Compared to fully automatic high-capacity filling lines, this cost-effective filling system offers a significantly lower investment cost. It is ideal for growing businesses, seasonal production, or facilities planning gradual capacity expansion.

Suitable Product Types

The MACLINE filling nozzle is not limited to ketchup and mayonnaise. It is also suitable for:

- Ketchup

- Mayonnaise

- Mustard

- Barbecue sauce

- Ranch and salad dressings

- High-viscosity emulsions

- Tomato and pepper pastes

- Pomegranate molasses, lemon sauce, and other thick liquids

This versatility makes it an excellent choice for manufacturers seeking a reliable industrial sauce filling nozzle.

Integration with Production Lines and MACLINE Systems

The filling nozzle is designed to work seamlessly with MACLINE’s vacuum cooking unit, homogenizer, and pasteurizer. It can be easily integrated into existing production lines and paired with optional equipment such as automatic